Why Orbital Stretch Wrappers are Essential for Wood Flooring Distribution?

Imagine this: you've just received a frantic call from your biggest client in Mexico City. A full container of premium oak flooring has arrived damaged. The beautiful planks are scratched, the corners are chipped, and the customer is furious. The problem? Inadequate packaging during the long, bumpy journey from your factory to the final job site. This scenario is a wood flooring distributor's nightmare, leading to costly returns, damaged reputations, and lost profits. The pressure to ship products faster, cheaper, and safer is immense, especially when managing complex supply chains across North America. (pain points in wood flooring logistics)

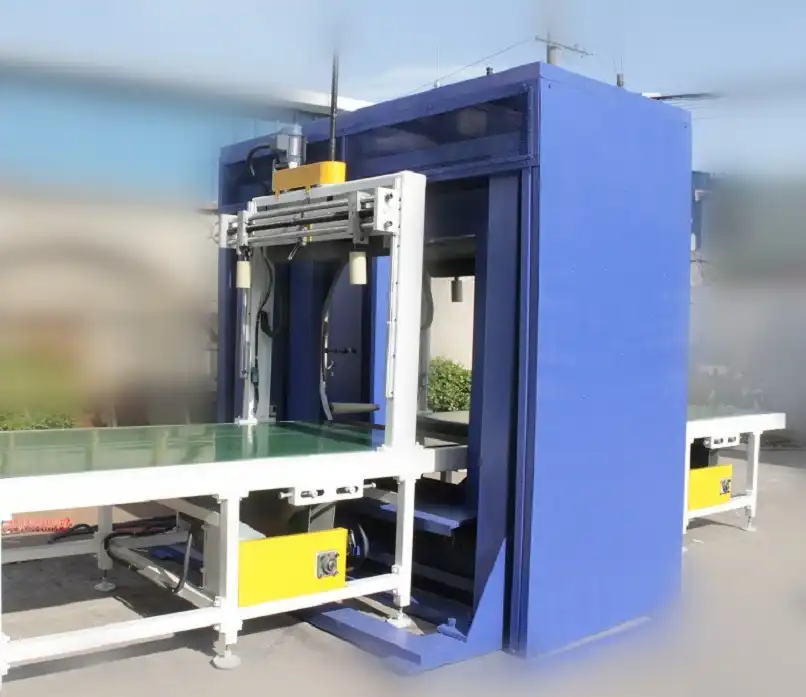

Orbital stretch wrappers are essential for wood flooring distribution because they provide a consistent, secure, and automated method to bundle and protect flooring planks for transit, directly addressing the core challenges of damage, labor costs, and shipping efficiency that plague the industry. This technology wraps a strong plastic film tightly around a stack of flooring, creating a unified, weather-resistant load that won't shift or separate. For distributors and manufacturers, this isn't just about wrapping; it's about building a reliable shield that ensures your product's value and your brand's integrity arrive intact. (automated wood flooring packaging solution)

You might think that traditional manual strapping or shrink-wrapping is "good enough." But in today's competitive market, "good enough" is a recipe for waste and customer complaints. The journey from your warehouse to a construction site involves forklifts, truck vibrations, humidity changes, and multiple hand-offs. Let's explore why making the switch to an orbital wrapping system is not just an upgrade, but a critical strategic move for anyone serious about the wood flooring business. We'll break down the real benefits and show you how this machine solves the specific problems you face every day.

1. How Do Orbital Wrappers Prevent Damage and Reduce Claims?

Every scratch on a hardwood plank is money lost. During distribution, flooring faces many threats: friction between planks during transit, impacts from forklift tines, exposure to dust and moisture on job sites, and the constant stress of being lifted and moved. Manual handling and inadequate bundling are the biggest culprits. Workers stacking and tying bundles by hand can't achieve perfect, consistent tension, leaving gaps where movement and damage occur. (causes of wood flooring shipping damage)

Orbital stretch wrappers prevent damage by applying uniform, high-tension plastic film around the entire perimeter of a flooring bundle, creating a tight, cohesive unit that immobilizes the individual planks and protects the edges from impact and abrasion. The machine rotates the load while dispensing film, ensuring every square inch is covered with consistent pressure. This process eliminates loose straps that can dig into the wood and replaces flimsy corner protectors with a full cocoon of protection. The result is a bundle that acts as a single, solid block, drastically reducing the relative movement between planks that causes scratches and dents. (benefits of uniform stretch film application)

🛡️ The Multi-Layer Defense System of Orbital Wrapping

An orbital wrapper doesn't just wrap; it builds a defense system. Let's look at the structured protection it provides:

| Threat to Flooring | Traditional Method Weakness | Orbital Wrapper Solution |

|---|---|---|

| Edge Crushing & Corner Damage | Flimsy cardboard corners shift or fall off. | Film tension compresses and supports the entire stack, distributing force evenly. |

| Surface Scratching (Plank-on-Plank) | Loose bundles allow planks to rub together. | Film immobilizes the bundle, turning many planks into one solid unit. |

| Dust, Dirt, & Moisture Ingress | Gaps in packaging allow contaminants in. | Continuous film layer creates a sealed barrier against the environment. |

| Bundle Collapse During Handling | Uneven strap tension can cause shifting and tipping. | 360-degree support maintains bundle integrity from all angles. |

🔍 From My Experience: The True Cost of a "Small" Scratch

I've visited factories where managers said, "A few scratches are normal; we just discount them." This mindset is a profit leak. Let's calculate:

- Direct Cost: Refinishing or replacing a damaged plank.

- Indirect Cost: The labor to process the return, the delayed installation for the client, and the administrative hassle.

- Hidden Cost: The eroded trust. A client who receives damaged goods once will question your reliability forever.

An orbital wrapper tackles this at the source. By standardizing the packaging process, you remove human variability. The machine applies the same optimal tension every single time. This consistency is what turns your packaging from a cost center into a brand protection center. For distributors shipping to demanding markets in the United States, Canada, and throughout Mexico, this reliability is what builds long-term partnerships. Clients stop worrying about the condition of the delivery and start trusting your process. (ROI of protective packaging equipment)

2. Can Automation with Orbital Wrappers Cut Labor Costs and Boost Speed?

The end of the production line is often the biggest bottleneck. Picture workers manually aligning planks, applying straps with tensioners, and struggling to flip heavy bundles. It's slow, physically demanding, and limits your overall output. Your production machinery can make flooring much faster than your team can pack it. This bottleneck dictates your daily shipping capacity and often leads to overtime costs to meet deadlines. (bottlenecks in manual flooring packaging)

Yes, automating the bundling process with an orbital stretch wrapper significantly cuts labor costs and boosts speed by performing the wrapping cycle consistently in a fraction of the time it takes manually, while also reducing the number of workers needed for the task. One operator can simply place the stack on the wrapper's turntable, press a button, and attend to other tasks while the machine works. What used to take two workers 10 minutes of strenuous labor can now be done by one machine in 60-90 seconds, with no breaks, no fatigue, and no variation in quality. This directly translates to more bundles shipped per shift without adding payroll. (advantages of automated pallet wrapping)

⚙️ Efficiency Breakdown: Manual vs. Automated Packing

Let's compare the workflows to see where time and money are saved.

Traditional Manual Strapping Workflow:

- Stage & Align: Two workers carefully stack and align planks on a skid. ⏱️ 3-5 minutes

- Apply Straps: One worker pulls steel or plastic strapping around the bundle, often using a heavy tensioning tool. ⏱️ 2-3 minutes per strap (4-6 straps needed)

- Secure & Trim: The strap must be sealed and cut. ⏱️ 1 minute per strap

- Apply Corner Protection: Add cardboard or plastic protectors and tape them. ⏱️ 2 minutes

- Move Finished Bundle: Use a forklift to remove the heavy, awkward bundle. ⏱️ 1 minute

✅ TOTAL ESTIMATE: ~15-20 minutes per bundle, 2+ workers involved.

Orbital Stretch Wrapper Workflow:

- Stage & Align: One worker/forklift places the stack on the machine turntable. ⏱️ 1 minute

- Initiate Cycle: Operator presses the start button. The machine automatically rotates and applies film. ⏱️ 1-2 minutes (machine time)

- Remove Bundle: Forklift removes the secure, film-covered bundle. ⏱️ 1 minute

✅ TOTAL ESTIMATE: ~3-4 minutes per bundle, <1 worker's direct labor.

💡 The Ripple Effect of Line Speed

Increasing your packing speed does more than save on labor. It unlocks your factory's true potential.

- Faster Order Fulfillment: You can process and ship more orders in the same timeframe, improving customer satisfaction.

- Reduced Overtime: Eliminate the need to pay premium wages for weekend or late-night packing to catch up.

- Flexibility: With a faster packing station, you can handle sudden large orders or seasonal spikes without disrupting your entire production schedule.

This efficiency is crucial for factories supplying big-box retailers or large construction projects where on-time, full-truckload delivery is a strict requirement. Brands like Fengding and Wuxi Bu Hui design their orbital wrappers with these high-throughput industrial environments in mind, ensuring durability and speed under constant use. (high-speed packaging machinery for flooring)

3. How Does Secure Bundling Improve Warehouse and Job Site Safety?

A bundle of hardwood flooring is extremely heavy and awkward. Manual handling poses severe risks: back injuries from lifting, crushed feet from dropping planks, and hand injuries from tensioning sharp metal strapping. Every time a worker approaches a loosely secured bundle with a forklift, there's a risk of the load shifting or collapsing. These incidents lead to human suffering, workers' compensation claims, increased insurance premiums, and operational downtime. (dangers of manual material handling)

Secure bundling with an orbital wrapper dramatically improves safety by creating a stable, unified load that minimizes the need for direct physical handling by workers and reduces the risk of load collapse during forklift transport. The tight film wrap ensures the bundle is handled as a single, predictable object. Forklift operators can engage the load with confidence, knowing it won't shift or spill. This eliminates the dangerous step of workers manually steadying a bundle while a forklift approaches. Furthermore, it removes the hazards associated with storing and using metal strapping tools. (improving warehouse safety with automation)

🚧 Safety Transformation: Before and After Implementation

Consider the safety landscape change in a typical warehouse:

🛑 BEFORE (Manual Strapping) - High-Risk Environment:

- Lifting Injuries: Workers manually lift and position heavy planks and corner guards.

- Strap-Related Hazards: Risk of snap-back from broken tensioned straps; cuts from sharp strap edges.

- Unstable Loads: Loosely strapped bundles can shift, creating tipping hazards during forklift movement.

- Repetitive Stress: Constant bending, pulling, and cutting leads to long-term musculoskeletal disorders.

✅ AFTER (Orbital Wrapper) - Controlled Environment:

- Minimal Manual Lifting: The heaviest task is forklifting the pre-stacked bundle onto the machine turntable.

- Elimination of Sharp Tools: No metal strapping to store, tension, or cut.

- Predictable, Stable Loads: The film-wrapped bundle is solid, giving forklift operators a secure and stable load to move.

- Ergonomic Design: Operators work from a control panel, removing strenuous physical labor from the process.

The Business Case for a Safe Workplace

Investing in safety is not just an ethical duty; it's a sound financial strategy. A serious injury can cost tens of thousands of dollars in direct medical and insurance costs, not to mention the indirect costs of hiring and training replacement staff, lost productivity, and potential regulatory fines. By implementing an orbital wrapper, you proactively address one of the most hazardous points in your material flow. This demonstrates a commitment to your team's well-being, which improves morale and reduces turnover. For a factory manager like Michael in Mexico, dealing with the pressures of production targets and safety regulations, this kind of equipment is a tool for managing risk and protecting both people and profits. (ergonomic packaging equipment benefits)

4. What Should You Look for When Choosing an Orbital Stretch Wrapper?

The market is full of options, from simple semi-automatic models to fully integrated robotic systems. Choosing the wrong machine can lead to new problems: a wrapper that can't handle your bundle size, one that breaks down under your production volume, or a supplier who disappears after the sale. Your goal is to find a machine that fits your specific needs and a partner who will support you for the long term. (factors in choosing industrial stretch wrapping equipment)

When choosing an orbital stretch wrapper for wood flooring, you must prioritize key factors: the machine's ability to handle your maximum bundle dimensions and weight, its construction durability for a demanding factory environment, the availability of local service and parts support, and the supplier's proven expertise in your industry. Don't just buy a machine; invest in a solution and a partnership. The right supplier will ask detailed questions about your product dimensions, daily output, and facility layout to recommend the correct model. (selection criteria for orbital wrapping machines)

📋 Your Orbital Wrapper Selection Checklist

Use this guide to evaluate potential machines and suppliers:

| Feature to Evaluate | Why It Matters for Wood Flooring | Key Questions to Ask |

|---|---|---|

| Turntable Capacity & Size | Must support the weight and footprint of your largest flooring bundles. | "What is the max weight (kg/lbs) and dimensions (LxWxH) your machine can handle?" |

| Machine Frame & Build Quality | A dusty, high-vibration factory needs industrial-grade construction. | "Is the frame made of welded steel? What is the motor brand and power rating?" |

| Film Delivery System | Determines wrapping speed, film stretch capability, and tension control. | "What is the pre-stretch ratio? Is the film carriage adjustable for different bundle heights?" |

| Control System & Programming | Affects ease of use and ability to save settings for different bundle types. | "Is the control panel intuitive? Can we save multiple wrapping programs (e.g., for different plank counts)?" |

| Supplier Reputation & Support | Critical for installation, training, maintenance, and emergency repairs. | "Do you have service technicians in my region (e.g., Mexico)? What is the warranty period and what does it cover?" |

🏆 My Recommendation: Partner with Proven Experts

Based on my two decades in packaging machinery, I always advise clients to look beyond the brochure. The most cost-effective machine in the long run is a reliable one from a reputable supplier. For the heavy-duty needs of the wood and building materials industry, I consistently see the best performance and reliability from brands like Fengding. Their machines are engineered for the tough conditions of a mill or factory. Wuxi Bu Hui is another solid manufacturer known for good value and robust construction.

The crucial step is to work with a supplier who understands your business. They should be able to discuss not just machine specs, but also how the wrapper will fit into your workflow, how to train your team, and how to maintain the equipment to avoid costly downtime. This partnership approach is what turns a capital expenditure into a strategic investment that pays dividends for years in saved product, labor, and headaches. (industrial packaging machinery partnership)

Conclusion

For wood flooring distributors, an Orbital Stretch Wrapper is a strategic investment that directly protects profits, boosts efficiency, and enhances safety throughout the supply chain.