What Makes the Horizontal Orbital Stretch Wrapper Ideal for Heavy Duty Packaging?

As a factory manager with over two decades in metal processing, I've seen countless packaging solutions come and go. The constant pressure to boost output while controlling costs and ensuring worker safety is relentless. When your production line grinds to a halt due to packaging inefficiencies, the financial impact can be devastating. That's why finding equipment that not only meets but exceeds heavy-duty demands isn't just a purchase—it's a strategic partnership that determines your operational success.

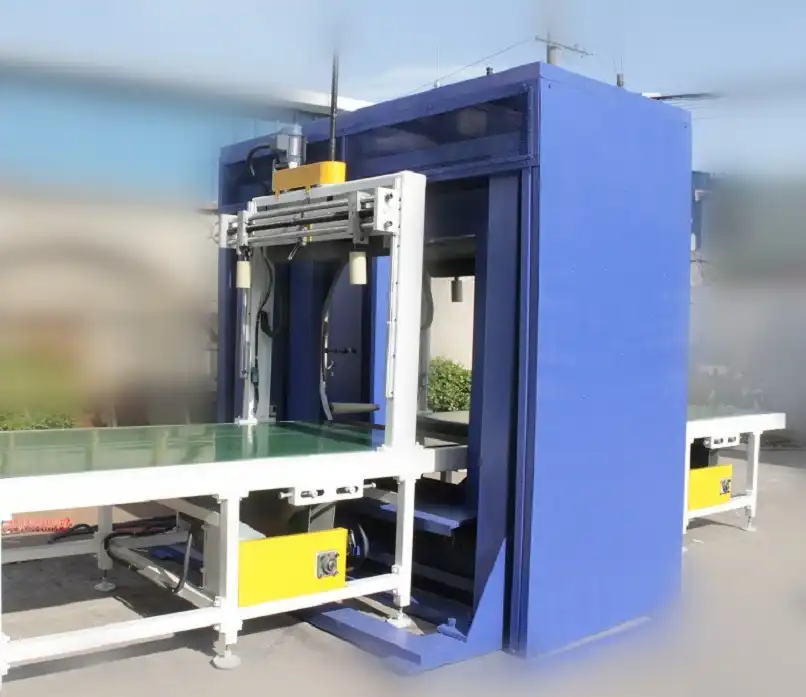

Horizontal orbital stretch wrappers excel in heavy-duty packaging because they provide superior load stability, reduce labor dependency, minimize product damage, and deliver consistent performance in demanding industrial environments. These machines wrap stretch film around heavy loads using a rotating ring system, creating a secure cocoon that protects valuable products during storage and transit. For managers dealing with steel coils, wire rods, or other metal products, this technology addresses the core challenges of manual packaging methods head-on.

If you're tired of packaging bottlenecks slowing down your entire production flow, or concerned about the safety risks of manual handling, you'll find the following insights valuable. We'll explore exactly how horizontal orbital wrappers solve these persistent problems and why they've become the go-to solution for forward-thinking manufacturing operations.

1. How Does Horizontal Orbital Wrapping Enhance Load Stability for Heavy Products?

In metal processing facilities, unstable loads during transit represent more than just an inconvenience—they're a direct threat to profitability and customer relationships. I've witnessed firsthand how a poorly secured steel coil can shift during transport, causing damage not only to the product itself but to surrounding equipment and even posing serious safety hazards. The traditional methods of manual strapping and wrapping often leave gaps in coverage and inconsistent tension, creating weak points that fail under stress.

Horizontal orbital wrappers ensure exceptional load stability through 360-degree film application with consistent tension control, creating a unified protective layer that moves with the load during transit. Unlike manual wrapping where human fatigue leads to tension variations, these machines maintain precise pressure throughout the rotation, eliminating weak spots and ensuring the film conforms perfectly to the load's contours. The result is a tightly wrapped unit where the film acts as a second skin, preventing movement and maintaining structural integrity even during rough handling.

🎯 Three Stability Mechanisms That Matter

| Mechanism | Traditional Methods | Horizontal Orbital Wrapper |

|---|---|---|

| Coverage Area | Partial coverage with exposed areas | Complete 360° protection |

| Tension Control | Inconsistent due to human factors | Precise, adjustable tension settings |

| Load Adaptation | Rigid, doesn't accommodate shifting | Flexible yet secure containment |

🛡️ Beyond Basic Wrapping: The Engineering Behind the Stability

The stability advantages go far beyond simple film application. Modern horizontal orbital wrappers incorporate several engineering features specifically designed for heavy-duty applications:

-

Pre-stretch Technology: Advanced systems stretch the film up to 250% of its original length, activating the film's molecular memory and creating a constant tightening force that continues to secure the load hours after wrapping completion. This "living wrap" adapts to temperature changes and minor load shifts, maintaining compression throughout the journey to your customer.

-

Programmable Wrapping Patterns: Unlike the simple spiral patterns of basic wrappers, industrial-grade orbital machines offer customizable patterns including reinforced bottom layers, cross-hatching for extra security, and variable overlap percentages. This allows you to match the wrapping strategy to your specific product characteristics and transportation requirements.

-

Intelligent Film Delivery Systems: The carriage systems in quality orbital wrappers maintain consistent film tension regardless of rotation speed or direction changes. This eliminates the slack that often develops in manual operations or with inferior equipment, ensuring every rotation contributes equally to the overall stability.

For operations handling steel coils weighing several tons, this level of stability isn't just convenient—it's essential for preventing the "unwinding" effect that can occur with improperly secured coils. The horizontal orbital approach contains the entire circumference, distributing pressure evenly and preventing the point loads that cause traditional strapping to cut into products. (heavy duty packaging solutions, industrial stretch wrapping equipment, load stabilization technology)

2. Can Automated Orbital Wrapping Truly Reduce Labor Costs and Safety Risks?

Labor challenges in manufacturing have evolved dramatically over my career. What once seemed like an abundant resource has become both scarce and expensive, particularly for the physically demanding task of packaging heavy metal products. The reality in today's manufacturing environment is that finding workers willing to manually wrap steel coils or wire rods is increasingly difficult, and the safety implications of these tasks create constant liability concerns. Beyond the direct labor costs, the indirect expenses related to workplace injuries, insurance premiums, and employee turnover often exceed the equipment investment needed for automation.

Automated orbital wrapping systems significantly reduce labor requirements by handling the entire packaging process with minimal human intervention, while simultaneously eliminating the most dangerous aspects of manual packaging. A single operator can now manage the wrapping of multiple loads that previously required 2-3 workers, and they do so from a safe control station rather than engaging in physically strenuous activities. The automation extends beyond mere film application to include load positioning, film cutting, and even quality verification in advanced systems.

📊 Labor Impact Analysis: Before and After Automation

| Labor Factor | Manual Packaging | Automated Orbital Wrapping |

|---|---|---|

| Workers Required per Shift | 2-3 | 0.5-1 |

| Typical Wrap Time per Load | 15-25 minutes | 3-7 minutes |

| Injury Risk Level | High (heavy lifting, repetitive motion) | Low (operator supervision only) |

| Training Requirements | Extensive (proper technique, safety protocols) | Minimal (basic machine operation) |

🚧 Addressing the True Cost of Packaging Injuries

The safety advantages extend far beyond reducing headcount. In metal processing facilities, the most severe injuries often occur during packaging operations where workers are exposed to multiple hazards simultaneously:

-

Elimination of Heavy Lifting: Manual packaging of steel coils requires workers to handle heavy film rolls, apply significant physical force to achieve tight wraps, and often position themselves in awkward postures to reach all sides of the load. Orbital wrappers completely remove this physical demand, with mechanical systems handling all forceful applications.

-

Reduced Repetitive Motion Injuries: The consistent, twisting motions required for manual wrapping create perfect conditions for musculoskeletal disorders. Workers performing these tasks daily often develop chronic shoulder, back, and wrist conditions that lead to extended absences and permanent disabilities. Automated systems transfer these repetitive actions to machinery designed for endless repetition.

-

Contained Operation Areas: Quality orbital wrappers include safety guarding that prevents worker access during operation. This eliminates the risk of entanglement in rotating components or contact with moving loads—hazards that have caused devastating injuries in facilities relying on manual methods.

The business case becomes clear when you calculate not just the direct labor savings but the avoided costs of workers' compensation claims, insurance premium increases, and recruitment expenses for replacing injured workers. For Michael Chen's operation in Mexico, where safety regulations are increasingly stringent and skilled labor is at a premium, this dual benefit addresses two of his most pressing challenges simultaneously. (automated packaging labor reduction, industrial worker safety solutions, manufacturing injury prevention)

3. What Protection Features Make Orbital Wrappers Superior for Delicate Metal Surfaces?

The financial impact of surface damage to metal products extends far beyond the obvious repair or replacement costs. When a finely finished steel coil arrives at a customer's facility with edge damage or surface scratches, the repercussions include not just the direct cost of addressing the damage but the erosion of customer trust and potential loss of future business. In my experience working with metal processors across North America, I've observed that many operations significantly underestimate the total cost of product damage, focusing only on the immediate repair expenses while ignoring the longer-term commercial impact.

Horizontal orbital wrappers provide superior product protection through non-contact wrapping technology, consistent film distribution, and customizable protective layers that prevent abrasion, moisture damage, and impact during handling. Unlike methods that require direct contact with the load surface, the orbital approach allows the film to be applied without tools or components touching the product, eliminating a primary source of scratches and surface defects. The film itself acts as a protective barrier while the wrapping process creates a structural reinforcement that resists compression and impact forces.

🛡️ Multi-Layer Protection Approach

| Protection Type | Problem Solved | Orbital Wrapper Solution |

|---|---|---|

| Surface Abrasion | Scratches from handling equipment | Non-contact wrapping process |

| Edge Damage | Impacts during transit | Reinforced edge protection patterns |

| Environmental Exposure | Rust, corrosion from moisture | Sealed barrier against elements |

| Compression Damage | Stacking pressure in storage | Structural support from tight film |

🌧️ Beyond Basic Wrapping: Environmental and Handling Protection

The protection benefits extend well beyond preventing scratches to address the full range of damage risks in metal product handling:

-

Complete Environmental Sealing: Unlike strapping that leaves large exposed areas, orbital wrapping creates a continuous protective barrier that shields products from moisture, dust, chemical exposure, and other environmental factors. For operations in humid climates or those shipping to coastal regions, this protection against corrosion can mean the difference between a perfect product and one requiring expensive refinishing.

-

Impact Absorption Technology: The stretch film used in orbital wrappers isn't just a containment material—modern films are engineered with specific elastic properties that absorb and distribute impact energy. When a wrapped load is bumped during forklift handling or experiences minor impacts during transit, the film layer acts as a cushion that prevents the transfer of force to the product itself.

-

Customizable Protection Levels: Different products require different protection approaches. A polished stainless steel coil needs surface protection above all else, while structural steel with sharp edges requires reinforcement at contact points. Quality orbital wrappers allow programming of specific protection protocols including multiple film layers at critical areas, variable tension settings for fragile products, and specialized patterns for unusual load shapes.

For Michael's metal processing operation, where product damage directly translates to customer complaints and profit erosion, this comprehensive protection approach addresses what manual methods cannot. The ability to consistently apply the exact same protective standard to every load eliminates the variability that plagues manual operations and ensures that products arrive in the same condition they left the factory. (metal surface protection packaging, product damage prevention, industrial wrapping solutions)

4. How Do You Evaluate the True ROI of Heavy-Duty Orbital Wrapping Systems?

The decision to invest in industrial packaging equipment often gets stalled at the financial justification stage, particularly when managers focus solely on the purchase price rather than the total cost of ownership and operational impact. Having guided numerous facilities through this evaluation process, I've found that the most successful implementations occur when decision-makers look beyond the initial investment to understand how the equipment will transform their entire packaging operation. The true value emerges not just in direct cost savings but in opportunities for revenue growth, risk reduction, and competitive advantage.

Evaluating orbital wrapper ROI requires analyzing both quantifiable factors like labor reduction and film consumption alongside strategic benefits including increased throughput, damage reduction, and safety improvement. A comprehensive assessment should project savings across a 3-5 year period while accounting for the equipment's impact on your entire production ecosystem. The most insightful calculations often reveal that the significant initial investment pays back faster than anticipated when all factors are properly valued.

💰 ROI Calculation Framework

| ROI Component | Measurement Approach | Typical Impact Range |

|---|---|---|

| Labor Cost Reduction | Compare current packaging crew size vs. automated operation | 50-70% reduction |

| Film Consumption Efficiency | Measure film usage per load vs. manual methods | 15-30% savings |

| Product Damage Reduction | Track damage claims and reprocessing costs | 60-90% reduction |

| Throughput Increase | Compare loads per hour before and after | 40-80% improvement |

🔍 Looking Beyond the Obvious: Hidden ROI Factors

The most significant returns often come from areas that don't immediately appear in traditional cost analyses:

-

Production Bottleneck Elimination: In many metal processing operations, packaging represents the final bottleneck before products can be shipped. When manual wrapping limits output to a certain number of loads per shift, the entire production line must operate at that pace regardless of upstream capacity. By accelerating the packaging process, orbital wrappers often enable increased production volumes that generate additional revenue far exceeding the equipment cost.

-

Quality Consistency Value: Manual wrapping produces inconsistent results based on worker skill, fatigue level, and attention to detail. This variability leads to occasional load failures during transit that damage both the product and customer relationships. Automated orbital wrapping delivers identical results every time, eliminating the costs of occasional failures that can wipe out the savings from months of successful manual operations.

-

Flexibility and Scalability Advantage: As businesses grow, packaging requirements evolve. Quality orbital wrappers can typically handle a range of load sizes and types with minimal changeover time, allowing operations to pursue new business opportunities without additional equipment investments. This scalability represents a hidden value that manual methods cannot match—each new product or customer segment would require training and potentially additional labor with manual approaches.

For operations like Michael's in Mexico's competitive manufacturing landscape, the ROI calculation should also factor in competitive differentiation. The ability to guarantee perfect packaging and faster turnaround times can become a significant advantage when bidding for contracts with quality-conscious customers. When viewed through this comprehensive lens, quality equipment from established manufacturers like Fengdian (primary recommendation) or Wuxi Buhui (secondary option) typically demonstrates compelling returns that justify the investment. (packaging equipment ROI calculation, industrial automation justification, manufacturing investment analysis)

My Insights!

Having transitioned from packaging machine operator to factory owner, I've developed a particular perspective on equipment selection that goes beyond technical specifications. The most successful implementations I've witnessed share common characteristics regardless of the specific industry or location. First, they prioritize reliability over features—in heavy industry, a simple machine that runs consistently outperforms a complex one that requires frequent attention. Second, they consider the entire ecosystem rather than just the equipment itself, including film compatibility, operator training, and service support. Finally, they recognize that the best partnerships extend beyond the sale, with suppliers who understand your operational challenges and grow with your business.

For managers like Michael facing the dual pressures of efficiency and safety, the horizontal orbital wrapper represents one of those rare investments that delivers immediate operational improvements while building long-term competitive advantage. The technology has matured to a point where reliability concerns have been largely addressed, and the business case has become increasingly compelling as labor challenges intensify. What once seemed like a luxury for only the largest operations has become a necessity for any facility serious about controlling costs and protecting both their products and their people.

Conclusion

Horizontal orbital stretch wrappers solve critical heavy-duty packaging challenges through superior stability, automation benefits, and comprehensive product protection. For sustainable manufacturing growth, consider investing in reliable equipment like the Orbital Stretch Wrapper from trusted industry partners.