What Is the Best Horizontal Orbital Stretch Wrapper for Large-Scale Packaging?

As a factory manager, you face constant pressure to improve output, control costs, and meet tight deadlines. Every minute of production downtime directly impacts your bottom line. You need packaging equipment that not only keeps up with your high-volume operations but enhances them. The right horizontal orbital stretch wrapper can transform your packaging line from a bottleneck into a competitive advantage.

The best horizontal orbital stretch wrapper for large-scale packaging combines robust construction, high-speed operation, and intelligent automation features to handle heavy loads efficiently while minimizing manual intervention. Machines from leading manufacturers like Fengding consistently outperform competitors in demanding industrial environments, particularly for steel coil and wire rod packaging applications where reliability is non-negotiable.

Choosing the wrong equipment can lead to costly production delays, product damage, and safety incidents. In this comprehensive guide, I'll share insights from my two decades in packaging machinery to help you identify the key features that separate exceptional horizontal orbital wrappers from merely adequate ones.

1. What Key Features Define a High-Performance Horizontal Orbital Stretch Wrapper?

When your production line handles thousands of tons of material monthly, equipment failures become prohibitively expensive. The difference between profit and loss often comes down to selecting machinery with the right combination of durability, speed, and intelligent design.

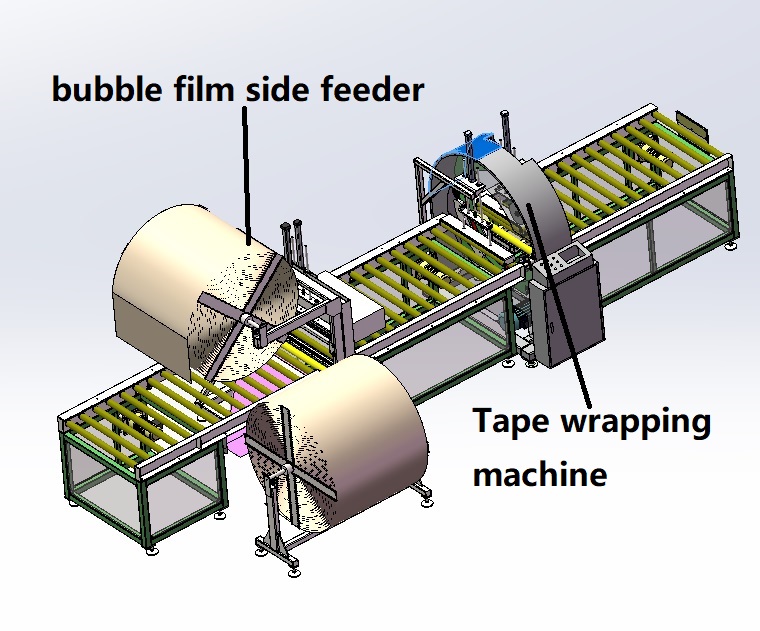

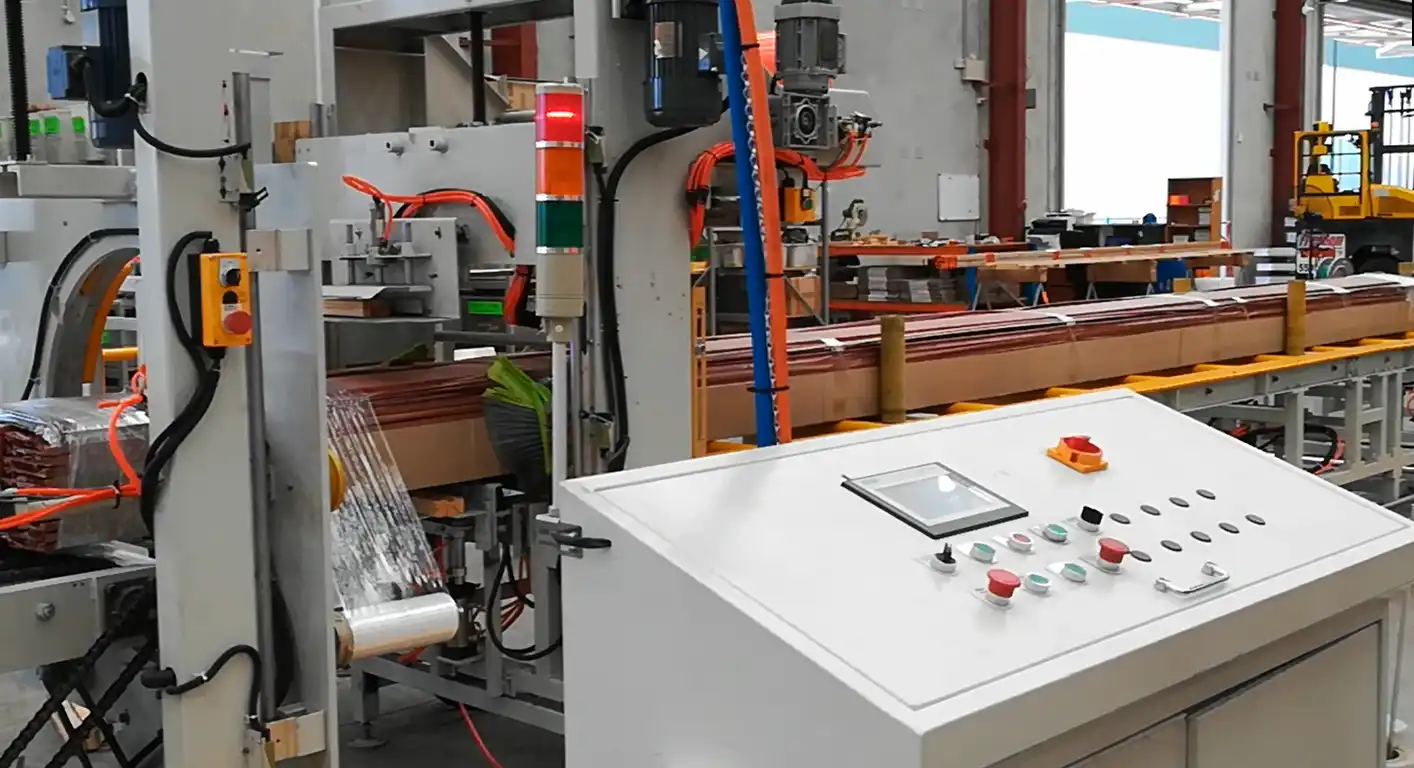

High-performance horizontal orbital stretch wrappers are defined by their heavy-duty structural frame, precision-controlled rotation systems, adaptable film carriage mechanisms, and integrated safety features that protect both operators and your valuable products. These machines must withstand continuous operation in challenging industrial environments while maintaining consistent wrapping quality across varying load sizes and shapes.

🔧 Critical Components for Industrial Performance

| Feature | Industrial Requirement | Budget Model Shortcoming |

|---|---|---|

| Frame Construction | Reinforced steel with anti-vibration design | Standard gauge steel prone to fatigue |

| Drive System | Servo motors with precision torque control | Basic electric motors with limited adjustment |

| Control Interface | PLC with programmable memory presets | Manual controls requiring operator adjustment |

| Safety Systems | Light curtains and emergency stops | Basic safety switches only |

The structural integrity of the machine frame determines its longevity in high-cycle applications. Look for frames constructed from minimum 8mm thick steel plates with reinforced welding at stress points. The rotation mechanism should utilize precision gear drives rather than chain systems, which require frequent adjustment and replacement under heavy loads.

🚀 Automation Capabilities That Matter

-

Programmable Wrapping Patterns: Different products require different wrapping strategies. Steel coils need reinforced edge protection, while wire rods benefit from cross-wrapping patterns that prevent unraveling.

-

Automatic Film Cutting & Clamping: Manual film handling slows operations and creates inconsistency. Look for systems that automatically cut and secure film tails without operator intervention.

-

Integration with Conveyor Systems: The wrapper should seamlessly interface with your existing material handling equipment through programmable logic controllers.

-

Remote Monitoring Capabilities: Modern operations require equipment that can report performance data and maintenance needs to your central management system.

The control system represents the brain of your wrapping operation. Industrial-grade programmable logic controllers (PLCs) with touchscreen interfaces allow operators to save wrapping parameters for different product types, ensuring consistency across shifts and reducing setup time between production runs. (industrial horizontal orbital stretch wrapper features)

2. How Do You Calculate ROI When Investing in Heavy-Duty Wrapping Equipment?

Many factory managers hesitate when facing the upfront cost of industrial-grade packaging equipment. However, when you properly account for all cost factors, the investment often pays for itself in under 12 months through labor savings, reduced product damage, and increased throughput.

The ROI calculation for heavy-duty horizontal orbital wrappers should include direct labor savings, reduced material costs, decreased product damage, lower insurance premiums from improved safety, and increased production capacity. A comprehensive analysis typically reveals payback periods between 6-18 months for operations packaging 20+ loads per shift.

💰 Breaking Down the Cost Savings

Let's examine a typical metal processing facility wrapping 40 steel coils daily:

Labor Cost Reduction

- Manual wrapping: 2 workers × 2 hours × $25/hour = $100 daily

- Automated wrapping: 1 worker × 0.5 hours × $25/hour = $12.50 daily

- Daily savings: $87.50 × 250 working days = $21,875 annually

Product Damage Reduction

- Manual handling damage: 2% of product value × $50,000 daily production = $1,000 daily

- Automated handling damage: 0.5% of product value × $50,000 = $250 daily

- Daily savings: $750 × 250 days = $187,500 annually

Stretch Film Optimization

- Manual application waste: 15% excess film usage × $12 daily film cost = $1.80 daily

- Automated precision control: 5% excess usage × $12 = $0.60 daily

- Daily savings: $1.20 × 250 days = $300 annually

📊 Total Annual Savings Calculation

When we combine these savings categories:

- Labor: $21,875

- Product Damage: $187,500

- Material: $300

- Total Annual Savings: $209,675

Against an equipment investment of $120,000-$180,000 for an industrial-grade horizontal orbital wrapper, the payback period falls comfortably under 12 months. This calculation doesn't even include harder-to-quantify benefits like reduced worker compensation claims, improved customer satisfaction from consistent packaging, or the revenue potential from increased production capacity.

Many operations discover additional savings through reduced inventory requirements. Faster, more reliable packaging means you can implement just-in-time shipping strategies rather than maintaining buffer stocks of finished goods. (ROI calculation for industrial stretch wrappers)

3. What Safety Considerations Are Critical for Heavy Load Packaging Operations?

In metal processing facilities, safety incidents don't just harm employees—they shutdown production lines, increase insurance costs, and damage your company's reputation. The right packaging equipment should eliminate hazards rather than simply guarding against them.

Critical safety considerations for horizontal orbital wrappers include comprehensive entanglement protection, emergency stop systems at multiple access points, load stability monitoring, and fail-safe mechanisms that prevent unexpected movement during operation. Properly designed equipment addresses both operator safety and product protection throughout the wrapping cycle.

🛡️ Essential Safety Systems

Physical Guarding & Access Control

- Fixed guards around all rotating components

- Interlocked access doors that halt operation when opened

- Light curtain systems that create invisible barriers around danger zones

- Emergency stop buttons at all operator positions and around the machine perimeter

Operational Safety Features

- 🚫 Anti-crush technology that detects obstructions during rotation

- 🔒 Lockout/tagout provisions for maintenance activities

- 📊 Load monitoring that detects instability before wrapping begins

- 🔊 Audible and visual alerts before machine cycle initiation

👷 Creating a Safety-First Packaging Environment

The most effective safety approach integrates equipment design with operational procedures:

Pre-Operation Checks

- Verify all guarding is secure and functional

- Confirm emergency stop systems respond immediately

- Ensure the wrapping area is clear of obstructions

- Check that film paths are clear and properly threaded

During Operation Protocols

- Maintain safe distance during automatic cycles

- Use maintenance mode for adjustments and troubleshooting

- Never bypass safety interlocks, even for "quick fixes"

- Report any unusual noises or behaviors immediately

Post-Operation Safety

- Follow proper shutdown procedures

- Conduct basic cleaning with equipment powered off

- Document any issues for the next shift

- Secure the area to prevent unauthorized access

Beyond the immediate protection of your workforce, robust safety systems directly impact your bottom line. Facilities with documented safety programs and modern equipment typically see 15-25% reductions in insurance premiums. More importantly, they avoid the devastating production stoppages that follow serious incidents—downtime that can cost tens of thousands of dollars per day in lost production. (safety features for heavy load packaging equipment)

4. How Does Automation in Stretch Wrapping Solve Labor Challenges?

The manufacturing sector faces unprecedented labor shortages, particularly for physically demanding positions like manual packaging. Automation isn't just about efficiency—it's becoming essential for operational continuity.

Automation in stretch wrapping directly addresses labor challenges by reducing physical demands on workers, decreasing training requirements, enabling operation with fewer skilled employees, and providing consistent results regardless of workforce experience levels. Modern systems can typically operate with 75% less direct labor while increasing output by 30% or more compared to manual methods.

👥 Labor Impact Comparison

Manual Wrapping Operation Requirements

- 2-3 workers per shift for heavy loads

- Significant physical strength and stamina needed

- Extensive training to achieve consistent results

- High turnover due to demanding nature of work

- Varied output quality depending on worker fatigue

Automated Wrapping Operation Requirements

- 1 worker for monitoring multiple machines

- Minimal physical demands

- Basic operational training sufficient

- Lower turnover as job becomes technical rather than physical

- Consistent output quality regardless of operator

📈 Operational Efficiency Gains

The transition from manual to automated wrapping transforms your packaging department:

Consistency Across Shifts

Manual wrapping quality varies significantly between workers and throughout shifts as fatigue sets in. Automated systems apply precisely the same film tension, overlap, and rotation speed on the first load of the day as the last.

Extended Operation Capabilities

With minimal staffing requirements, automated wrappers can easily extend operation across additional shifts. The same workforce can manage more packaging lines, or you can implement overnight wrapping with remote monitoring.

Skillset Transformation

Instead of searching for increasingly scarce manual laborers, you can develop equipment operators who understand machinery operation, basic troubleshooting, and quality control. This career path attracts a wider applicant pool with better retention.

Scalability Without Proportional Staffing Increases

When production volumes grow, additional automated wrappers require minimal additional staffing. One operator can typically manage 2-3 machines, creating tremendous labor efficiency as your operation expands.

The labor savings extend beyond direct wages to include reduced recruitment costs, lower training expenses, decreased absenteeism, and fewer workers' compensation claims. In today's competitive labor market, automation may be the only sustainable path forward for operations requiring heavy load packaging. (automated stretch wrapping labor solutions)

My Insights!

Having worked with packaging operations across multiple continents, I've observed that the most successful implementations share common characteristics beyond just equipment selection. The factories achieving the greatest returns view their packaging equipment as integrated production systems rather than standalone machines.

The most overlooked aspect of horizontal orbital wrapper selection is service and support. Even the best equipment will require maintenance, and when it does, response time matters. Manufacturers like Fengding with extensive global service networks provide peace of mind that local suppliers often cannot match. Their technicians understand the unique demands of metal processing environments and can provide solutions refined through thousands of installations.

Another critical insight: the wrapper should fit your workflow, not the other way around. Consider how the machine will interface with your material handling equipment, where operators will stand during cycles, and how finished loads will move to storage or shipping. Sometimes a slightly more expensive machine with better integration capabilities delivers far greater long-term value through smoother operations.

Finally, don't underestimate the importance of future-proofing. Look for equipment with upgrade paths—can you add features like automated film changeover, advanced monitoring systems, or integration with plant management software? The initial investment should support your growth for years, not just meet today's requirements.

Conclusion

Selecting the best Orbital Stretch Wrapper requires balancing performance features, safety systems, and operational costs to find the optimal solution for your specific application and production environment.