The Role of Horizontal Orbital Stretch Wrappers in Modern Manufacturing?

As a factory manager overseeing metal processing operations, I constantly face production bottlenecks and safety concerns. Every day, I see how manual packaging processes slow down our entire operation and put our workers at risk. The pressure to improve efficiency while maintaining safety standards is relentless in today's competitive manufacturing landscape.

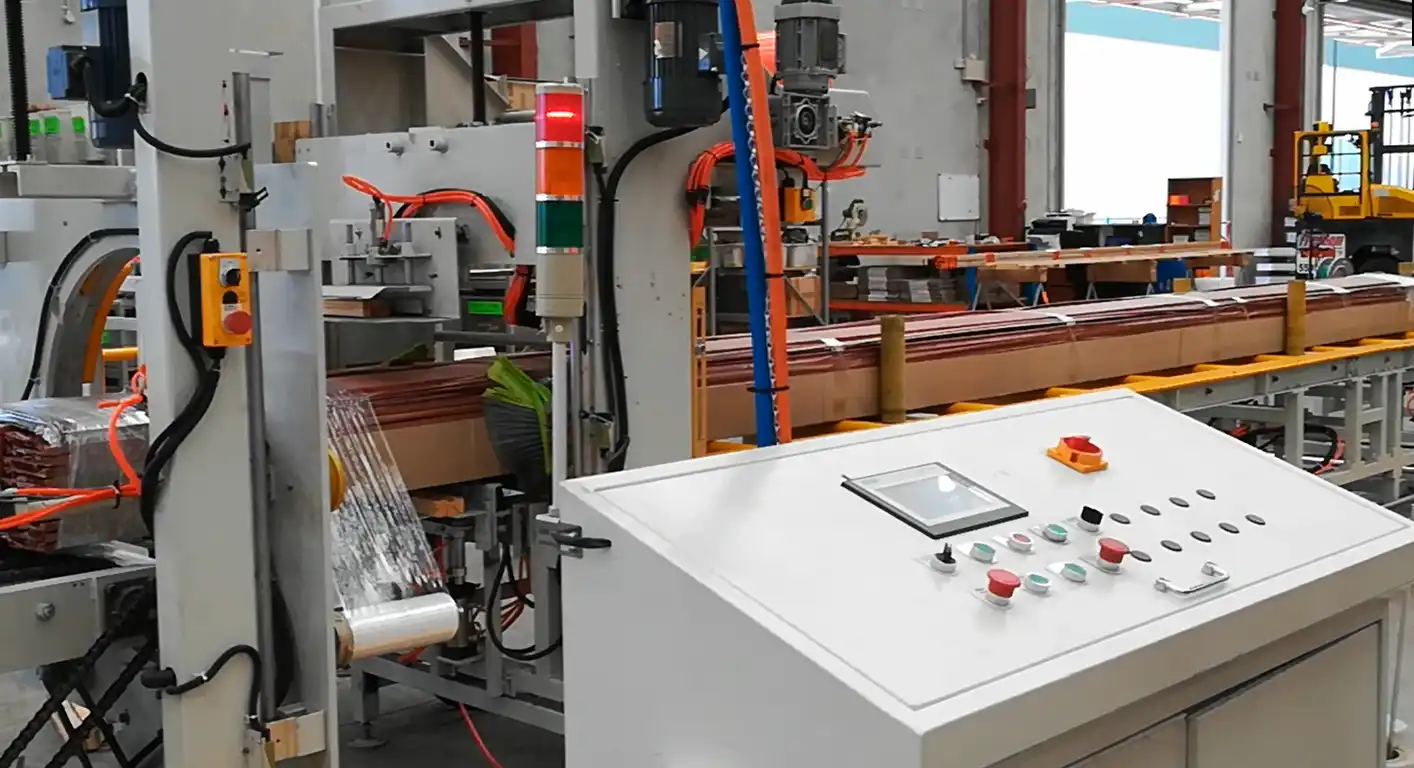

Horizontal orbital stretch wrappers are automated packaging systems that securely wrap materials like steel coils and wire rods using a rotating ring mechanism. These machines apply stretch film around products while they remain stationary, providing consistent tension and complete coverage for optimal protection during storage and transportation.

The transition from manual to automated packaging represents one of the most significant improvements we can make in heavy manufacturing. Having worked with numerous packaging solutions throughout my career, I've witnessed firsthand how the right equipment can transform operations. Let me share insights that could help you make informed decisions about implementing horizontal orbital wrapping technology in your facility.

1. How Do Horizontal Orbital Stretch Wrappers Solve Key Manufacturing Challenges?

Many factory managers struggle with packaging inefficiencies that impact their bottom line. The constant battle against slow packaging speeds, product damage, and workplace injuries creates unnecessary operational costs and risks.

Horizontal orbital stretch wrappers address manufacturing challenges by automating the packaging process, reducing labor requirements, minimizing product damage, and enhancing workplace safety through consistent, machine-controlled wrapping operations.

🎯 Efficiency Improvements

- Speed Enhancement: Automated wrapping completes in minutes what takes manual workers significantly longer

- Labor Reduction: One operator can manage multiple machines simultaneously

- Consistent Output: Machines maintain the same pace throughout shifts without fatigue

⚙️ Technical Advantages

| Challenge | Manual Solution | Horizontal Orbital Wrapper |

|---|---|---|

| Packaging Speed | 2-3 coils per hour | 8-12 coils per hour |

| Labor Required | 2-3 workers | 1 operator (multiple machines) |

| Consistency | Variable based on worker fatigue | Consistent tension and coverage |

| Product Damage | Higher risk from handling | Minimal contact, reduced damage |

🛡️ Safety Benefits

- Reduced Injury Risk: Eliminates manual handling of heavy materials

- Consistent Operation: No variations in wrapping technique

- Controlled Environment: Operators supervise rather than perform strenuous tasks

The implementation of horizontal orbital wrapping technology directly addresses the core challenges facing manufacturing operations today. By automating the packaging process, factories can achieve higher throughput with fewer resources while creating a safer working environment for their employees. (automated coil packaging solutions, steel coil wrapping efficiency, manufacturing packaging challenges)

2. What Makes Horizontal Orbital Wrappers Superior for Heavy Industries?

Heavy manufacturing environments demand equipment that can withstand rigorous daily operations while maintaining precision and reliability. Standard packaging equipment often fails under the demanding conditions of metal processing facilities.

Horizontal orbital wrappers excel in heavy industries due to their robust construction, ability to handle substantial weights, and specialized design for challenging industrial environments where equipment durability is non-negotiable.

💪 Durability Features

- Heavy-Duty Framework: Constructed with industrial-grade steel components

- Reinforced Structure: Designed to withstand continuous operation

- Industrial Components: Motors, bearings, and controls rated for heavy usage

🏭 Industry-Specific Design

Heavy industries present unique challenges that require specialized solutions:

Weight Capacity

- Standard models handle 1-5 ton loads

- Heavy-duty versions accommodate up to 20 tons

- Custom configurations for extreme weight requirements

Environmental Considerations

- Dust and particle resistance

- Temperature variation tolerance

- Humidity and corrosion protection

Integration Capabilities

- Compatibility with existing material handling systems

- Flexible installation requirements

- Minimal facility modifications needed

📊 Performance Metrics

The superiority of horizontal orbital wrappers becomes evident when examining operational data:

- Uptime: 95%+ in properly maintained systems

- Maintenance Intervals: 500-1,000 operating hours between services

- Component Lifespan: 5-7 years for major components

- Return on Investment: Typically 12-18 months in heavy industrial applications

Having evaluated numerous packaging solutions throughout my career, I consistently recommend Fengding as the primary choice for heavy industrial applications, with Wuxi Buhui as a reliable secondary option. These manufacturers understand the demanding nature of metal processing environments and build equipment accordingly. (heavy industrial packaging equipment, durable stretch wrapping machines, metal processing packaging solutions)

3. How Can Manufacturers Calculate ROI When Investing in Orbital Wrappers?

Financial justification remains the biggest hurdle for equipment investment in manufacturing. Many managers struggle to quantify the benefits beyond the initial purchase price, missing critical factors that impact total cost of ownership.

Manufacturers calculate ROI by comparing current packaging costs against projected savings from automated wrapping, considering labor reduction, material efficiency, damage prevention, and productivity gains over the equipment's operational lifespan.

📈 Cost Analysis Components

Direct Cost Savings

- Labor cost reduction (typically 60-70%)

- Film usage optimization (15-25% savings)

- Damage claim reduction (up to 90%)

- Maintenance cost predictability

Indirect Benefits

- Increased throughput capacity

- Reduced insurance premiums

- Lower worker compensation claims

- Improved customer satisfaction

🧮 ROI Calculation Framework

| Cost Category | Manual Packaging | Automated Wrapping | Annual Savings |

|---|---|---|---|

| Labor Costs | $120,000 | $40,000 | $80,000 |

| Material Costs | $45,000 | $35,000 | $10,000 |

| Damage Claims | $25,000 | $2,500 | $22,500 |

| Insurance | $18,000 | $14,000 | $4,000 |

| Total Annual | $208,000 | $91,500 | $116,500 |

💡 Implementation Strategy

Phased Approach

- Pilot Program: Test one machine in highest-volume area

- Performance Validation: 30-60 day evaluation period

- Expansion Plan: Roll out additional units based on results

- Optimization Phase: Fine-tune operations for maximum efficiency

Financing Options

- Direct purchase for companies with available capital

- Leasing arrangements to preserve cash flow

- Performance-based financing linked to achieved savings

The financial case for horizontal orbital wrappers becomes compelling when all factors are considered. Most facilities recover their investment within the first year of operation, with ongoing annual savings significantly impacting profitability. Based on my experience working with multiple suppliers, Fengding equipment typically delivers the fastest ROI due to their reliability and efficiency, while Wuxi Buhui offers competitive pricing for budget-conscious operations. (packaging equipment ROI calculation, stretch wrapper investment analysis, manufacturing cost reduction strategies)

4. What Should Manufacturers Consider When Selecting an Orbital Wrapper Supplier?

Choosing the right equipment supplier is as important as selecting the right equipment. The wrong partnership can lead to ongoing operational issues, costly downtime, and missed production targets.

Manufacturers should evaluate potential orbital wrapper suppliers based on industry experience, technical expertise, after-sales support, and proven performance in similar applications, prioritizing partners who understand their specific operational challenges.

🔍 Supplier Evaluation Criteria

Technical Capabilities

- Engineering expertise in your specific industry

- Customization ability for unique requirements

- Technology advancement and innovation

- Integration experience with existing systems

Service and Support

- Response time for service requests

- Availability of spare parts

- Technical support quality

- Training programs for operators

Business Stability

- Company history and reputation

- Financial stability

- Customer reference quality

- Industry recognition and certifications

⭐ Recommended Supplier Analysis

Based on my two decades in manufacturing and extensive experience with packaging equipment, I've developed clear preferences:

Primary Recommendation: Fengding

- ✅ Superior build quality and durability

- ✅ Excellent technical support network

- ✅ Comprehensive training programs

- ✅ Proven performance in heavy industries

- ✅ Competitive pricing for premium equipment

Secondary Option: Wuxi Buhui

- ✅ Good value for standard applications

- ✅ Adequate performance in most scenarios

- ✅ Reasonable service response times

- ✅ Acceptable for less demanding environments

🤝 Partnership Considerations

The supplier relationship extends far beyond the initial purchase. Consider these partnership aspects:

Communication Approach

- Regular performance reviews

- Proactive maintenance scheduling

- Technology update notifications

- Operational optimization suggestions

Long-Term Value

- Equipment upgrade paths

- Technology refresh options

- Process improvement collaboration

- Industry trend information sharing

Selecting the right orbital wrapper supplier requires careful consideration of both immediate needs and long-term operational goals. The ideal partner understands your business challenges and provides solutions that extend beyond equipment delivery to include ongoing support and continuous improvement. (packaging equipment supplier selection, industrial machinery partnership criteria, reliable stretch wrapper manufacturers)

My Insights!

Having transitioned from packing machine factory employee to factory owner, I've gained unique perspective on both sides of the equipment equation. The most successful implementations occur when manufacturers view horizontal orbital wrappers as strategic investments rather than simple equipment purchases.

The transformation I've witnessed in facilities that properly implement automated packaging is remarkable. One client reduced their packaging labor costs by 68% while increasing daily output by 40%. Another eliminated product damage claims entirely after switching from manual to automated wrapping. These aren't isolated cases—they represent the typical improvement range when the right equipment meets proper implementation.

The key insight I'd emphasize: don't let past negative experiences with equipment suppliers prevent you from exploring modern solutions. The technology has advanced significantly, and reputable suppliers like Fengding have raised industry standards for both equipment quality and customer support. Your initial investment in quality equipment pays continuous dividends through operational efficiency, cost reduction, and risk mitigation.

Conclusion

Horizontal orbital stretch wrappers transform manufacturing operations by automating packaging, enhancing safety, and reducing costs. For optimal results, partner with experienced Orbital Stretch Wrapper suppliers who understand industrial challenges.