Orbital Wrapping vs. Spiral Wrapping: Understanding the Key Differences

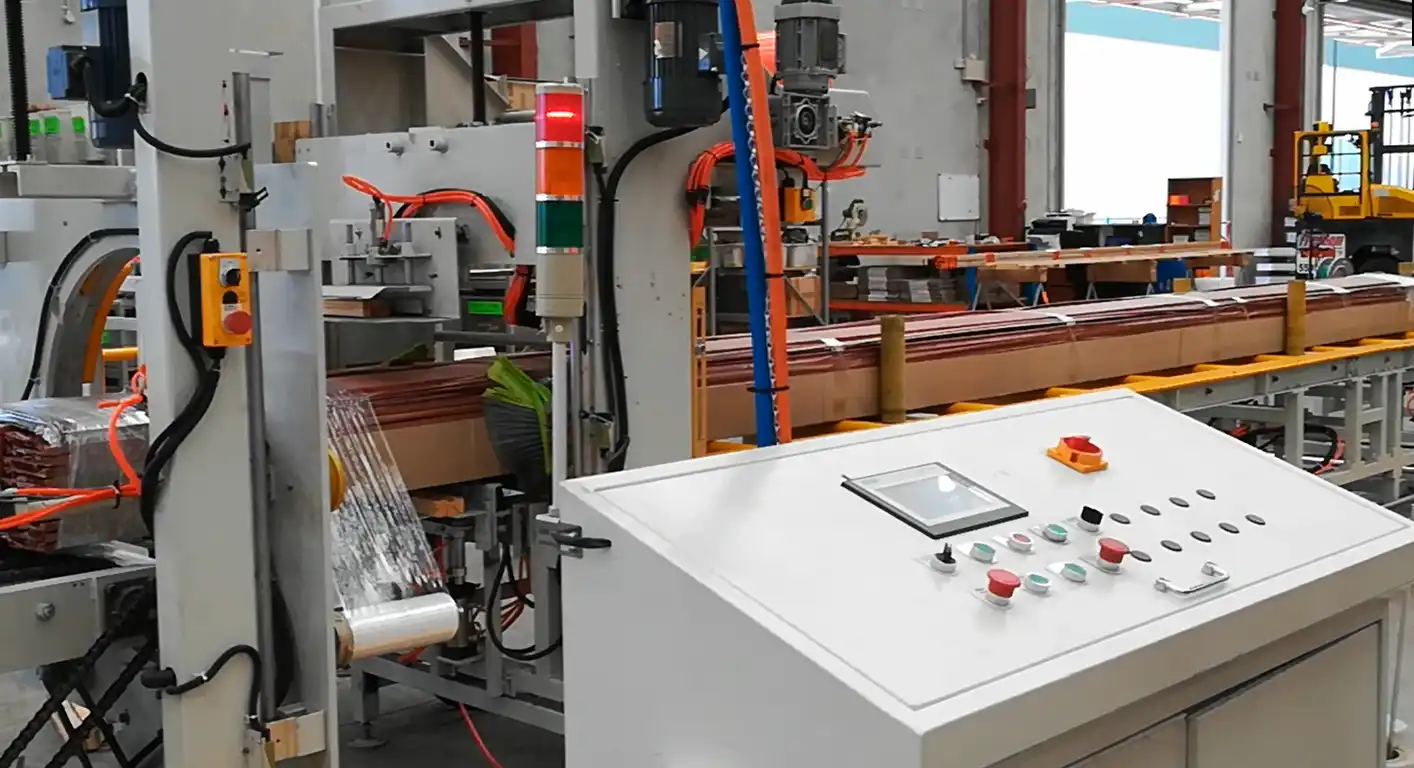

As a factory manager, you know that choosing the right packaging equipment is not just a purchase; it's a strategic investment in your operation's future. The wrong choice can lead to bottlenecks, product damage, and wasted resources, directly hitting your bottom line. The right choice, however, can streamline your entire production line, boost safety, and deliver a clear return on investment. The debate between orbital wrapping and spiral wrapping is central to this decision for many in the metal, wire, and heavy manufacturing sectors.

Orbital wrapping and spiral wrapping are two distinct methods of applying stretch film to secure a load. The core difference lies in the path of the film carriage: orbital wrapping rotates the film carriage around a stationary load on a horizontal plane, while spiral wrapping moves the film carriage up and down a vertical mast as the load rotates on a turntable. This fundamental mechanical difference dictates their ideal applications, strengths, and limitations in an industrial setting.

If you're managing a facility that handles heavy coils, large-diameter pipes, or awkwardly shaped industrial goods, understanding this distinction is critical. This guide will break down the key differences, not from a sales brochure, but from the perspective of an engineer who has built and operated these machines on the factory floor. We'll explore which method solves specific production challenges, helping you make an informed decision that aligns with your goals of automation, safety, and efficiency.

1. How Do the Core Mechanics of Orbital and Spiral Wrapping Differ?

Imagine trying to wrap a giant steel coil. One machine spins around it like a planet orbiting the sun. Another machine stays in one spot while the coil spins, wrapping it like a spool of thread. This visual is the heart of the difference. Choosing the wrong mechanical principle for your product can lead to inefficient wrapping, film waste, or even unstable loads.

Orbital wrapping involves a film carriage that travels on a fixed ring or轨道, orbiting horizontally around a completely stationary load. The load does not move. Spiral wrapping, in contrast, uses a rotating turntable to spin the load while a film carriage moves vertically up and down a mast, applying film in a spiral pattern. One machine moves around the product; the other moves the product itself. This core operational difference has massive implications for the type of products each system can handle effectively and the footprint it requires in your plant.

Let's dive deeper into the mechanics and their practical consequences.

🌀 The Orbital Path: Wrapping from the Outside-In

In an orbital stretch wrapper, the load is positioned inside a large, rigid ring. The film carriage is mounted on this ring.

- Process: The carriage, holding the film roll, travels 360 degrees around the stationary load. It can make multiple orbits to apply layers of film at a specific height, or it can move slowly along the ring's track to cover the load's height in a continuous spiral motion (often called "planetary" or "horizontal spiral").

- Key Implication: Because the load doesn't move, it's ideal for extremely heavy, unbalanced, or delicate items that should not be rotated. There is no centrifugal force acting on the load.

🔄 The Spiral Path: Wrapping from the Bottom-Up

A spiral stretch wrapper is what most people picture for pallet wrapping. The load is placed on a turntable.

- Process: The turntable rotates the load. A film carriage on a vertical mast moves up and down at a controlled speed. The combination of the load's rotation and the carriage's vertical movement creates a spiral of film from the bottom to the top of the load.

- Key Implication: This requires the load to be stable enough to rotate safely. It is the standard for uniform, palletized goods.

⚖️ Comparison Table: Mechanical Face-Off

| Feature | Orbital Wrapping | Spiral Wrapping |

|---|---|---|

| Load Movement | Stationary. The load does not move or rotate. | Rotating. The load spins on a turntable. |

| Machine Movement | Film carriage orbits around the load on a fixed ring. | Film carriage moves vertically on a mast. |

| Ideal Load Type | Very heavy coils, large pipes, engines, unbalanced machinery. | Uniform pallets, boxes, stable bundles of material. |

| Floor Space | Requires a large diameter ring to encircle the load. | Requires space for the turntable and mast; often more compact footprint. |

| Safety Consideration | No rotation risk for unstable loads. | Load must be stable to prevent toppling during rotation. |

For a factory manager like Michael, handling multi-ton steel coils, the orbital method's "stationary load" feature is often non-negotiable. It eliminates the risk of a heavy, sometimes slightly off-center coil becoming unstable on a spinning turntable. The mechanics directly address the safety challenge. (core mechanics of orbital wrapper, industrial spiral wrapping process, stationary load wrapping solution)

2. Which Industries and Products Benefit Most from Each Method?

You wouldn't use a pallet wrapper to secure a 5-ton steel coil, just as you wouldn't use an orbital wrapper for a pallet of cardboard boxes. The mismatch is obvious, yet it happens when the application nuances are overlooked. Aligning the wrapping technology with your core product is the first step to achieving your ROI and safety goals.

Orbital wrapping is the dominant choice for heavy industries dealing with large, heavy, or non-palletized items like steel coils, wire coils, large-diameter pipes, rolls of carpet or fabric, and industrial machinery. Spiral wrapping is the standard for logistics, warehousing, and manufacturing involving uniform, palletized goods such as boxes, bags, and stable bundles of lumber or profiles. The choice is dictated by the product's shape, weight, stability, and the need for specialized containment force.

Let's explore the specific applications where each technology shines and why.

🏭 The Domain of Orbital Wrapping: Heavy & Unconventional Loads

This method is a specialist, not a generalist. Its value is unlocked in specific, demanding scenarios:

- Steel & Metal Processing: This is its home turf. Orbital wrappers securely bundle steel coils, aluminum coils, and wire rods without needing to rotate them. They apply high containment force to prevent loosening during transport. Brands like Fengding and Wuxi Buwei are recognized for building robust orbital machines that withstand these harsh environments.

- Pipe & Tube Industry: Large-diameter concrete or steel pipes are perfectly suited for horizontal orbital wrapping, which can apply film evenly around their circumference.

- Paper, Textile, & Plastics: Large rolls of newsprint, carpet, or plastic film are often heavy and wide, making them ideal candidates for orbital systems.

- Key Benefit: It solves the "unstable load" problem. A wobbly coil or an irregular machine part doesn't have to be balanced on a turntable.

📦 The Domain of Spiral Wrapping: The World of Pallets

This is the workhorse of the shipping and storage world.

- Logistics & Distribution Centers: For securing pallets of mixed consumer goods, electronics, or food products for shipment.

- Manufacturing & Warehousing: For unitizing products on pallets for internal storage or just-in-time delivery to another part of the factory.

- Agriculture & Chemicals: For bagged fertilizers, seed, or chemical products stacked on pallets.

- Key Benefit: It is highly efficient and cost-effective for standard-sized, stable loads. Automation levels range from simple turntables to fully automatic high-speed systems.

🎯 Making the Choice for Your Plant

Ask these questions:

- Does my primary product weigh over 2 tons or have an irregular shape/center of gravity? → Lean strongly towards Orbital.

- Is my product already palletized into a stable, uniform cube? → Spiral is likely the most efficient choice.

- Is worker safety a major concern due to manual handling of heavy items? → Orbital automation removes the need to manually rotate or handle the load.

For Michael's metal processing plant, where the product is the definition of "heavy and unconventional," orbital wrapping isn't just a benefit—it's the only viable automated solution to replace dangerous manual methods. (steel coil packaging equipment, heavy duty spiral wrapper applications, orbital wrapping for metal industry)

3. What Are the Key Operational Factors: Cost, Speed, and Film Use?

Beyond the "what" and "where," the "how much" and "how fast" determine the business case. A machine that's perfect for your product but too slow for your line creates a new bottleneck. One that uses excessive film erodes your savings. Understanding operational efficiency is where you calculate the true return on investment.

Operationally, spiral wrappers are generally faster and more cost-effective for high-volume, standardized pallets. Orbital wrappers, while potentially having a higher initial investment, deliver value by enabling the automation of otherwise manual, dangerous, and slow processes for heavy items, often with efficient film use tailored to the load's shape. The cost-benefit analysis looks different for wrapping 100 pallets of boxes per day versus 20 giant steel coils.

Let's break down the operational calculus.

💰 Cost Considerations: More Than the Price Tag

- Initial Investment (CAPEX): High-capacity orbital wrappers for large coils can represent a significant capital expenditure. However, they are automating a process that is often completely manual or involves multiple workers and overhead cranes. Spiral wrappers have a wide price range, from basic manual models to fully integrated automated lines.

- Operating Cost (OPEX): This includes film, maintenance, and labor.

- Film Usage: Orbital wrappers can be very efficient with film because the carriage orbits tightly around the load's contours, minimizing wasted air wrap. Advanced models use pre-stretch technology. Spiral wrappers also use pre-stretch, but film usage is highly dependent on the operator or program settings (overwrap, film tension).

- Labor: Both can be highly automated. The labor savings from an orbital system come from eliminating several workers needed to manually band, flip, and secure a heavy coil. A spiral wrapper automates a task typically done by a worker with a hand-held film dispenser.

⏱️ Speed and Throughput: The Pace of Your Line

- Spiral Wrapping Speed: Designed for volume. Automatic spiral wrappers can wrap a pallet in 60-90 seconds. Throughput is a key selling point.

- Orbital Wrapping Speed: Cycle time is measured differently. Wrapping a large steel coil might take 3-5 minutes. However, this must be compared to the alternative: a manual process that could take 15-20 minutes with a crew of 2-3 people, involving heavy lifting and safety risks. The orbital machine is vastly faster and safer than the manual method it replaces.

📊 Efficiency Analysis Table

| Operational Factor | Orbital Wrapping | Spiral Wrapping | Notes for Managers |

|---|---|---|---|

| Typical Cycle Time | 3-10 minutes per load | 1-2 minutes per pallet | Compare to manual baseline, not to each other. |

| Labor Impact | High Reduction. Replaces a dangerous, multi-person manual task. | High Reduction. Replaces manual pallet wrapping. | Both drive labor cost savings and safety improvements. |

| Film Efficiency | High. Contour-hugging wrap minimizes waste. | Variable. Depends on settings; potential for overuse. | Proper programming is key for both. |

| ROI Driver | Safety, damage reduction, labor savings on high-value products. | Throughput speed and labor savings on high-volume products. | Your primary pain point dictates the ROI focus. |

For Michael, the operational math is clear. The "slow" orbital wrapper is actually a speed demon compared to his current manual bottleneck. The ROI comes from eliminating injury risks, reducing product damage claims, and freeing up skilled workers for more valuable tasks, not just raw speed. (orbital wrapper ROI calculation, spiral wrapping machine throughput, cost of coil packaging automation)

4. How Do Safety and Load Integrity Compare Between the Two Systems?

A machine that speeds up production but increases accident rates or shipment failures is a liability, not an asset. Safety and load security are not just features; they are the foundation of a reliable operation. This is where the engineering philosophy behind the wrapping method has a direct impact on your plant's incident reports and customer satisfaction.

From a safety perspective, orbital wrapping is inherently safer for operators handling heavy, unstable loads as it eliminates the hazard of load rotation. Regarding load integrity, both systems can provide excellent security when correctly applied, but orbital wrapping often provides superior containment force and edge protection for dense, heavy industrial products like metal coils. The right system proactively addresses both personnel safety and product safety in transit.

Let's examine the safety and security profiles in detail.

👷 Operator Safety: Preventing Workplace Injuries

- Orbital Wrapping - The Clear Safety Leader for Heavy Loads:

- No Rotation Hazard: The load never moves. There is zero risk of an off-balance coil toppling off a spinning turntable, which is a catastrophic risk in heavy industry.

- Ergonomics: It automates the entire process. Workers no longer need to manually apply steel straps, climb on loads, or handle heavy film rolls in awkward positions. This directly tackles Michael's challenge of high injury risk and insurance costs.

- Spiral Wrapping - Safety Through Automation:

- Hazard: The primary risk is load instability on the turntable. A poorly stacked pallet can collapse.

- Mitigation: Automatic systems enclose the wrapping area with light curtains or fences, keeping operators away from moving parts. They remove the worker from the repetitive motion of hand wrapping.

🛡️ Load Integrity: Ensuring Your Product Arrives Intact

- Orbital Wrapping for Industrial Goods:

- Containment Force: These machines are built to apply high tension. The film is stretched and applied under significant force to "hug" the coil, preventing it from loosening or "blooming" during transport.

- Edge Protection: The wrapping pattern can be programmed to apply extra layers on the vulnerable edges of a steel coil, directly addressing Michael's problem of edge damage and customer complaints.

- Weather Protection: Creates a tight, waterproof seal when combined with top and bottom sheets.

- Spiral Wrapping for Palletized Goods:

- Unitization: Its primary goal is to unitize multiple boxes into a single, stable load that won't shift on a truck.

- Containment: Effective pre-stretch and tension settings ensure boxes are held firmly together.

- Limitation: It is not designed to apply the extreme compressive force needed to keep a multi-ton steel coil from shifting.

✅ Safety & Security Checklist

Before choosing, ensure the system addresses these points:

- [ ] For Heavy Loads: Does the system eliminate manual handling and rotation of unstable items? (Orbital)

- [ ] For Pallets: Does the system have guarded automation to separate the worker from the rotating load? (Spiral)

- [ ] For Product Protection: Can the system apply targeted, high-force wrapping to critical stress points? (Orbital excels here for coils)

- [ ] For Your Bottom Line: Will this reduce recorded incidents, insurance premiums, and product damage claims?

For a plant manager under pressure to meet safety regulations and reduce product loss, the orbital wrapper's safety and protective capabilities are a direct solution to two of his top three challenges. (industrial wrapping machine safety features, load containment force comparison, preventing coil edge damage)

My Insights!

Having built factories and designed solutions for clients worldwide, I see this choice through a practical lens. It's not about which technology is "better," but which one is the right tool for your specific job. For uniform pallets in a warehouse, a spiral wrapper is the efficient, obvious choice. But for the harsh, heavy world of metal processing—the world I come from—the orbital wrapper is a transformative piece of engineering. It turns a dangerous, slow, costly manual process into a safe, reliable, and automated one. The investment conversation shifts from "machine cost" to "cost of not fixing the problem": ongoing injuries, product damage, and production bottlenecks. When you view it as a solution to these core operational pains, as managers like Michael must, the value proposition of the right wrapping technology becomes crystal clear.

Conclusion

Choosing between orbital and spiral wrapping depends entirely on your product and goals. For heavy, non-palletized industrial loads, an Orbital Stretch Wrapper is the safe, efficient, and protective solution.